Thread: HF English Wheel

-

11-26-2012 11:42 PM #16

Maybe one answer to this would be to buy the extra set of HF wheels and send them off to Pat to have him straighten them out.Hummmm

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

11-29-2012 10:04 AM #17

The wheels are ok, at least the set i have are ok. People that have a problem with the HF wheels is because the alignment is out of whack between the upper and lower anvil. That would be a real problem, esp if you have to use a radiused wheel on the lower anvil.

We need to get Robert (M.P.& C, i think) to chime in here. He built a wheel and used a super nice set of upper and lower anvils and wheels - hoosier maybe?

-

11-29-2012 10:32 AM #18

Yeah,I remember on one of the metal working sites a guy here in Roch that build a really nice heavy duty E-Wheel.I don't remember his name or which site it was on.He had to move it around with a cherry picker it so heavy.

-

11-29-2012 12:20 PM #19

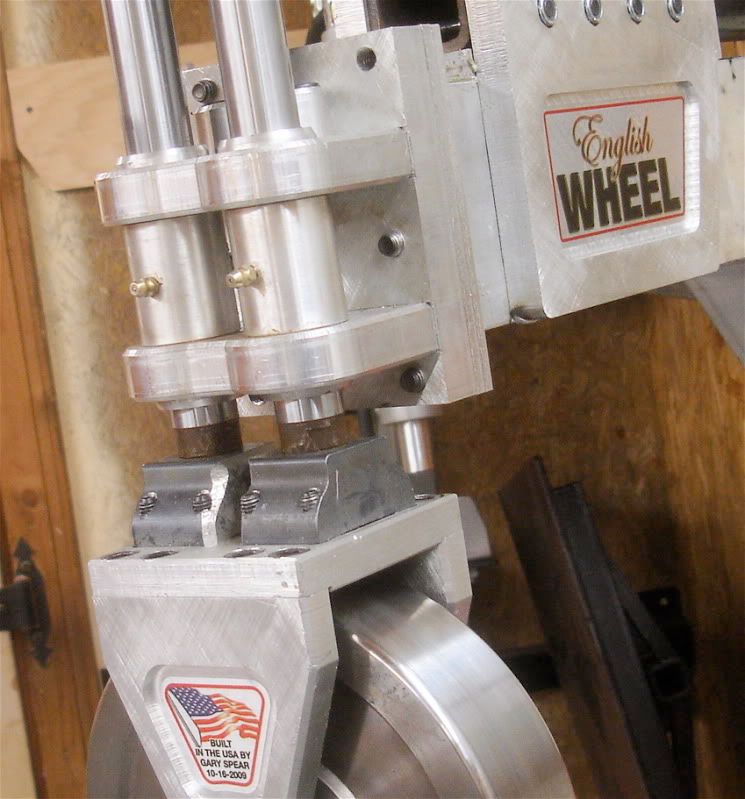

I bought HF wheels (radius) & have not had any problems with them. Built a frame that's stiffened by clamping it in the wall w/receivers. 2''x4'' Aluminum tubing from the scrap yard for the frame makes it light enough to move out of the way but very little flex when it's clamped in place.

I was told on a metal forum that HF wheels wouldn't work & that my frame was way too light. When I got it done I formed this scrap piece of aluminum as a test. The slight marks you see in the photo couldn't be felt at all when I ran my hand over the peice. I've done quick projects where I've shot gloss rattle can paint over areas like this, only wiping the surface down with solvent, no sanding & you could not see the marks.

The reply I got, oh sure aluminum but it won't handle steel. So I posted this, & got no response, same smooth surface.

It may not be the best deal for a full time shop but it works fine for what I use it for.

and it's light enough to hang out of the way behind the door with the other metal shaping stuff when I need the space.

I also have a HF bead roller. Stiffened up the frame with thick wall 2''x2'' tube, replaced the crank with an old bicycle wheel, makes it much easier to control the bead.

None of the metal shaping tools are high dollar, took some time but not a huge amount of money. But, they do come in handy from time to time. I had as much fun building them as I do using them."PLAN" your life like you will live to 120.

"LIVE" your life like you could die tomorrow.

John 3:16

>>>>>>

-

12-01-2012 08:46 PM #20

As I read more of the threads on both Medalmeet and All Metalshaping I am committed to that type of work is what I want to be able to do. One project the guys there ask for in newbie is to make a smooth bowl with just hand tools.I'm not sure how soon I will have time to do that,but it is on the bucket list.

I'm going to go back to the fact everytime I make up my mind I want something,I find a way to get there.

10Likes

10Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Thanks guys! One more trip around the sun completed. Lots of blessings and things to be thankful for (like still being able to type this message!!) Here's to us "over 70 guys.." Glenn

HBD Glenn!!