Thread: Tig Welders- tell me more

-

11-24-2012 08:38 AM #1

Tig Welders- tell me more

The best tool I have my welder, want to step it up a bit and take the Tag plunge. Tig will offer me the ability to weld different materials with a finer control of the weld that a Mig lacks somewhat. As I see it the Tig works pretty much like gas welding, however with much better control of the heat.

So my question is about the Tig machine for the users, what brand do you prefer, what to look for, general rule of thumb when buying the machine. Foot control verses finger, what are the consumables filler rod and gas are known what else? The Tig I have in mind Miller Diversion 180 TIG Welder

What other manufactures might compare, I am concerned with the quality not cheap prices just to guide the responses.

Thanks in advance

pepiI have two brains, one is lost and the other is out looking for it

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

11-24-2012 08:52 AM #2

Miller is a good name. I don't often have a foot pedal, you can set the voltage and run with it. I love a finger trigger, nothing better. The only other consumable would be the titanium tips. (rods). You'll need a grinder to freshen up the tips.

Always wear gloves, else you'll get shocked by your filler rod..

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

11-24-2012 10:07 AM #3

I love my Tig Machine, although I find that as time goes by I use my Mig more (for Steel)-I was raised in a Town where I would ride my Bike down to the local Welder just to watch him, and was always intrigued by how Metal was bent and Welded-he used Lincoln exclusively, and, I believe that is why I like Lincoln (although they make good machines to boot )-

)-

I have Pro Tig 185 Lincoln, and I have outfitted it with finger control and a Gas Lens-I find the Gas lens offers better visibility and Gas control, so I use it whenever I can-couple that with Pulse control (a big deal to me, as I don't have to roll the controls to get the desired results)-with Pulse Control I can make Welds that look like the proverbial stack of Dimes-(although, with practice I can do it without it, but it's a lot easier)-

I think Miller makes a fine machine, and it's a shame you don't have a few of them to try side-by-side(some Welding Shops will let you test drive them)-

I have often thought if I should have gone with a bigger machine, but for me, a hobbiest, I don't think so-it just my opinion (your Mileage may vary ), but I think the Machines in this Amp range offer better low Amp control (in the 25-80 range)than others (which may give you better control on that 22 Gauge Stainless)-

), but I think the Machines in this Amp range offer better low Amp control (in the 25-80 range)than others (which may give you better control on that 22 Gauge Stainless)-

For me it also depends on where/when I can get consumables and Service-Have you ever noticed that anybody driving slower than you is an idiot, and anyone going faster than you is a maniac?

-George Carlin

-

11-24-2012 01:50 PM #4

I looked at the "Diversion" series, nice welder for the price....However if my memory serves me correctly it does not have pulse control.Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

11-24-2012 05:25 PM #5

I have a Lincoln Pro Tig 185 also. I am just starting to get "better" at welding aluminum. I am getting better at reading the puddle and keeping my hands coordinated but I still need some seat time to get the stack of dimes consistantly.

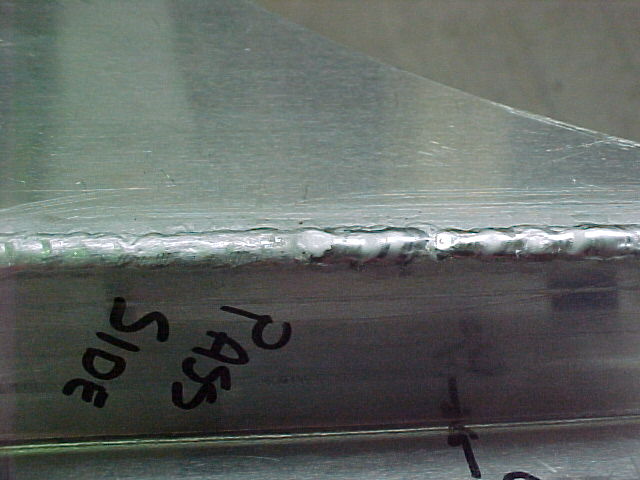

Here are a couple of welds I did today on my radiator shroud for the van. I was using a 1/16 pure tungsten electrode, a gas lens with a #8 cup and had the max amperage set at 90 with the foot control running at about 75%. I set the pulse at 1 per second and had the frequency set to "AUTO".

i still have a long way to go and fillet welds still kick my ass...

MarkLast edited by astroracer; 11-24-2012 at 05:29 PM.

If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-24-2012 07:27 PM #6

Thanks for the replies, I will check out the Lincoln Pro Tig 185 and see what I can learn. Dave that Miller does not have pulse as an option. Care to expand as to the necessity of that as a function? Is it a personal preference or helps the Tig welding, is pulse something that would be useful welding all metal types.

firebird77clone

Good point about the filler rod shocking the welder, read about the glove warning and shocking, but you have explained the HOW that happens thanks. I will remember that as I do not always use gloves when I Mig weld.

35window

You seem to prefer the Mig for steel, may I ask why that would be? Tig as I understand would lay down a cleaner bead and think Mig steel welding is faster then the Tig process.

Mark

Very funny comment I sure do understand the meaning...

Again thanks all for the input you have helped and I will do some more research.I have two brains, one is lost and the other is out looking for it

-

11-24-2012 07:57 PM #7

i have a big red machine .have used blue . i got my best bang for the buck with lincon machine . on my machine i could and did add the pluse controle panle on it at a latter date .i feel it a wast of money but looks cool more knobs. i have had 3 tig over the years all will work . my old round wave machine welded just as good as the square wave machine there some small things about the lincoln when welding alum but nothing to be gained on steel welding .but not any thing that could not be over come by cleaning the base metal better if you welding junk metal china stuff . no machine is going to make you shine. i like thumb wheel on the torch head as i use my welder off the table and over head if you are only welding on a table . many like the foot pedalIrish Diplomacy ..the ability to tell someone to go to Hell ,,So that they will look forward to to the trip

-

11-24-2012 08:06 PM #8

i weld all stuff with out gloves past 200 amps in a head port i may wear them or just one on torch hand. i feel the filler rod better never been shock but i and odd i may like it. filler rods all is cut and dry for the jobs and color if your buffing it you want to base metal to match filler have a handy filler rod book but i know most what works for what and keep good supply on handLast edited by pat mccarthy; 11-24-2012 at 08:30 PM.

Irish Diplomacy ..the ability to tell someone to go to Hell ,,So that they will look forward to to the trip

-

11-25-2012 05:54 AM #9

Probably more personal preference on Pulse control, as 35 explained, don't have to roll the control to get the nice welds. I'm also it would appear the only one so far who prefers foot control, probably just because I'm used to it and my hands don't work real well anyway......Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

11-25-2012 07:53 AM #10

Irish Diplomacy ..the ability to tell someone to go to Hell ,,So that they will look forward to to the trip

-

11-25-2012 09:00 AM #11

Yeah, I can see where they would be a lot more convenient. I tried a thumb control again the other day at a buddy's shop, unfortunately it seems old King Arthir has take over my right hand and I just can't seem to get the control I want on the heat so it looks like I'm stuck with the "gas pedal" control.....

I avoid working under a car like the plague anymore, have a heck of a time doing anything when I have to get my arms above my head. That's another reason I keep modifying and trying to perfect my rotisserie, seems to be about the only way I can work on a car anymore!!!Yesterday is history, tomorrow is a mystery, Live for Today!

Carroll Shelby

Learning must be difficult for those who already know it all!!!!

-

11-25-2012 04:59 PM #12

Pat I will not be doing the type of welding you do. The Tig will be for 1/8 too 3/16 stuff, steel some tubbing and Aluminum. Keeping the mig for 1/4 & 5/16, no head or block welding in the foreseeable future for me. I might get the weld done, but lack the machines to do the finish work.

"filler rod book " did not know there was such a book, going to scout that out thanks.

I like the idea of the trigger on the torch that foot peddle is an extra cord to trip over and all the other Murphy's laws that would apply. Jumping to a Tig welder cause I like the clean welds and having the ability of welding different materials.

Cars are a hobby for me, make some good side cash working on HotRods and welding broken stuff or building things people think up and need.Last edited by pepi; 11-25-2012 at 05:03 PM.

I have two brains, one is lost and the other is out looking for it

-

11-25-2012 05:59 PM #13

yep i did not think i said go buy a big machine BUT when i pick up mine i did not think i was going to weld some of the stuff i do

when i pick up mine i did not think i was going to weld some of the stuff i do i pick up a tig welder to work for becool never went any were as they at one time wanted me to build custom rads it did not work out i did not have the money to start up the shop. but was doing some of there cars and stands for there product line i was happy to burn alumiun together so i was no loss as at that time i was doing alot of fab work. when my old round wave machine was given me trouble i pick up the 275 machine now thinking back i should of pickup a bigger machine. the filler rod books may be hard to come by pocket size i have one by crown and a book for weldmold most have a cross over for other names for companys rods like missile . neptune so you can pick up the rod by a different company if need the only time i do not do this is on rod that i weld blocks with only use weldmold

i pick up a tig welder to work for becool never went any were as they at one time wanted me to build custom rads it did not work out i did not have the money to start up the shop. but was doing some of there cars and stands for there product line i was happy to burn alumiun together so i was no loss as at that time i was doing alot of fab work. when my old round wave machine was given me trouble i pick up the 275 machine now thinking back i should of pickup a bigger machine. the filler rod books may be hard to come by pocket size i have one by crown and a book for weldmold most have a cross over for other names for companys rods like missile . neptune so you can pick up the rod by a different company if need the only time i do not do this is on rod that i weld blocks with only use weldmold

Last edited by pat mccarthy; 11-25-2012 at 06:02 PM.

Irish Diplomacy ..the ability to tell someone to go to Hell ,,So that they will look forward to to the trip

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Thanks guys! One more trip around the sun completed. Lots of blessings and things to be thankful for (like still being able to type this message!!) Here's to us "over 70 guys.." Glenn

HBD Glenn!!