Thread: Lets see your tin work...

-

05-05-2013 07:53 PM #31

Spent yesterday at a metalshaping workshop, Gatormeet, in Frederick MD. Some of the projects:

1918 International Truck

Pontiac GTO door skin repair

55 Pontiac hood being fitted with GTO hood scoops

The major project was to fabricate new front fenders for the International truck. This was to include wiring the edge and adding a bead detail to match the original.

This little trick with a washer worked well to keep the wire tucked in nice and snug. Another option discussed was to use the roller found on a screen cording installation tool. While we didn't have one, the notch in the roller of this tool may work better to insure the washer doesn't slip off the wire.

Dies made for the Pullmax and installed to add the bead detail..

Using the highly precise rolling tool

Comparing the two new fenders

Other various pictures...

14 year old Cody was about the youngest attendee. He came with his grandfather, and as I had met both of them at OJ's workshop a couple months ago, when I saw Cody standing with his arms folded I felt obligated to grab him and put him to work on the International's fender. I told him he would learn more with a hammer in his hand. He was more involved after that, learning some tuck shrinking as you see here..

Overall a great time of sharing skills, ideas, and special thanks to Gator for hosting the event.

Here's some local news coverage of the Gatormeet from this weekend..

Gatormeet keeps art of metal shaping alive - The Frederick News-Post : PeopleLast edited by MP&C; 05-05-2013 at 07:57 PM.

Robert

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

05-07-2013 05:11 PM #32

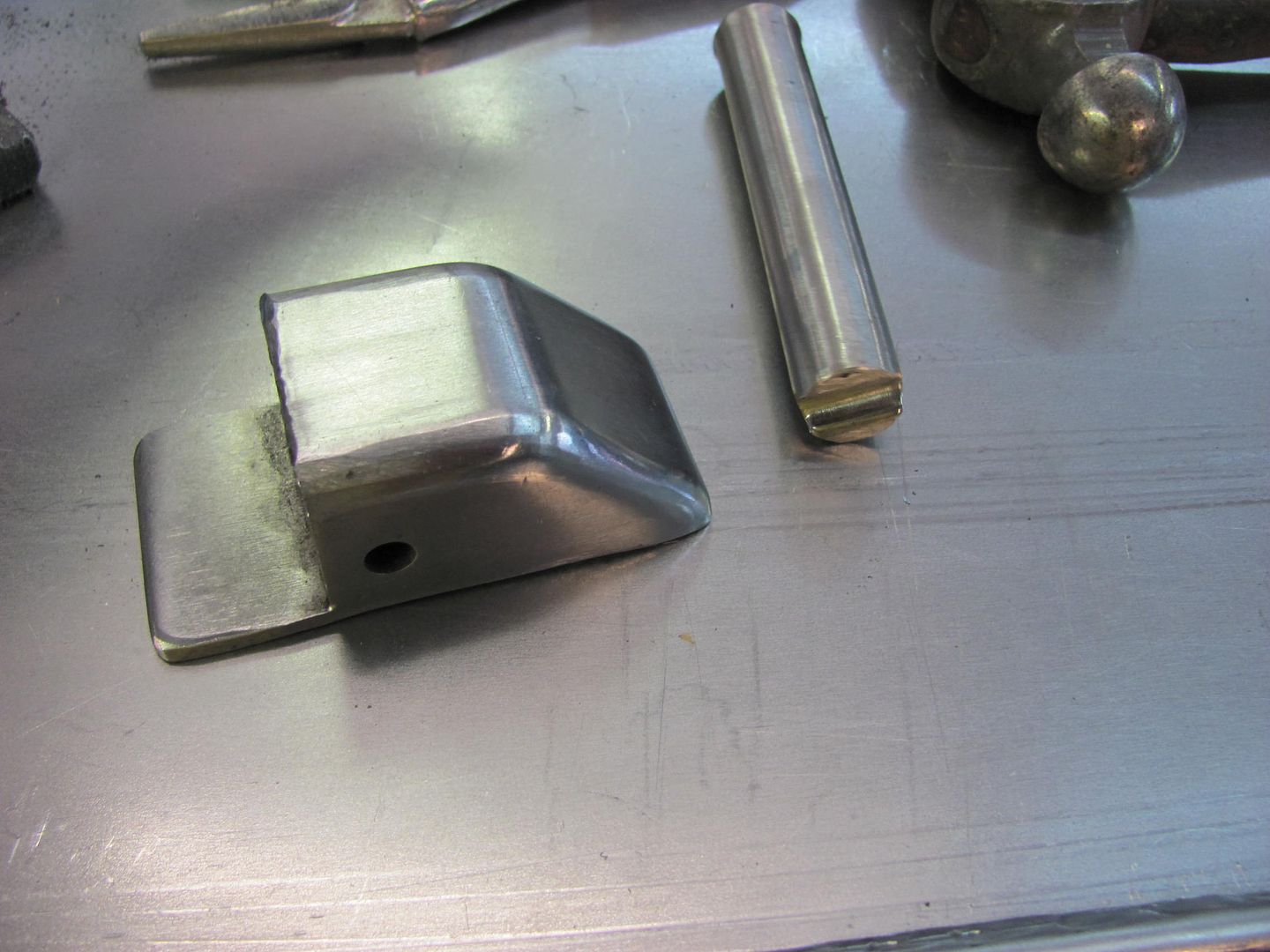

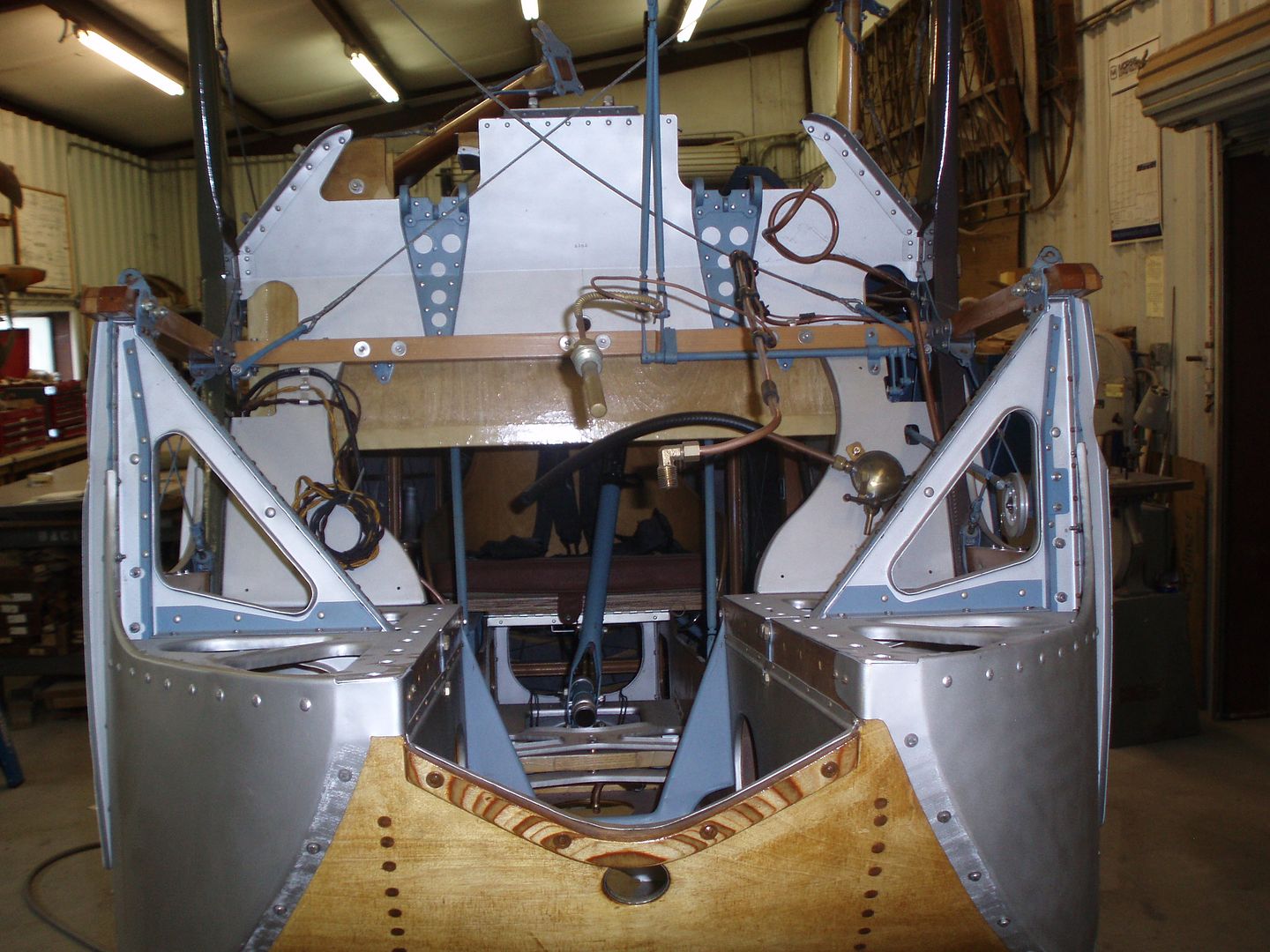

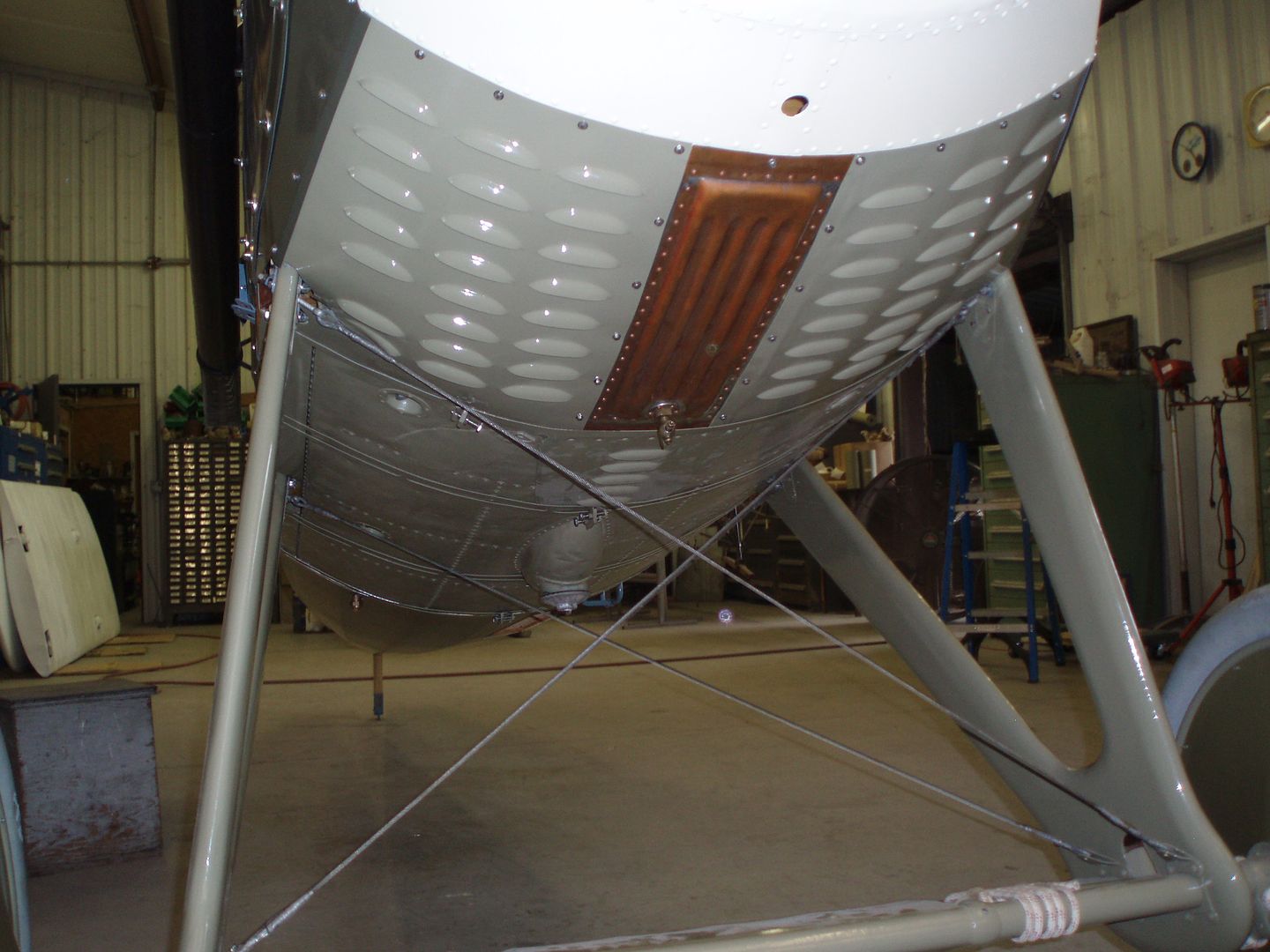

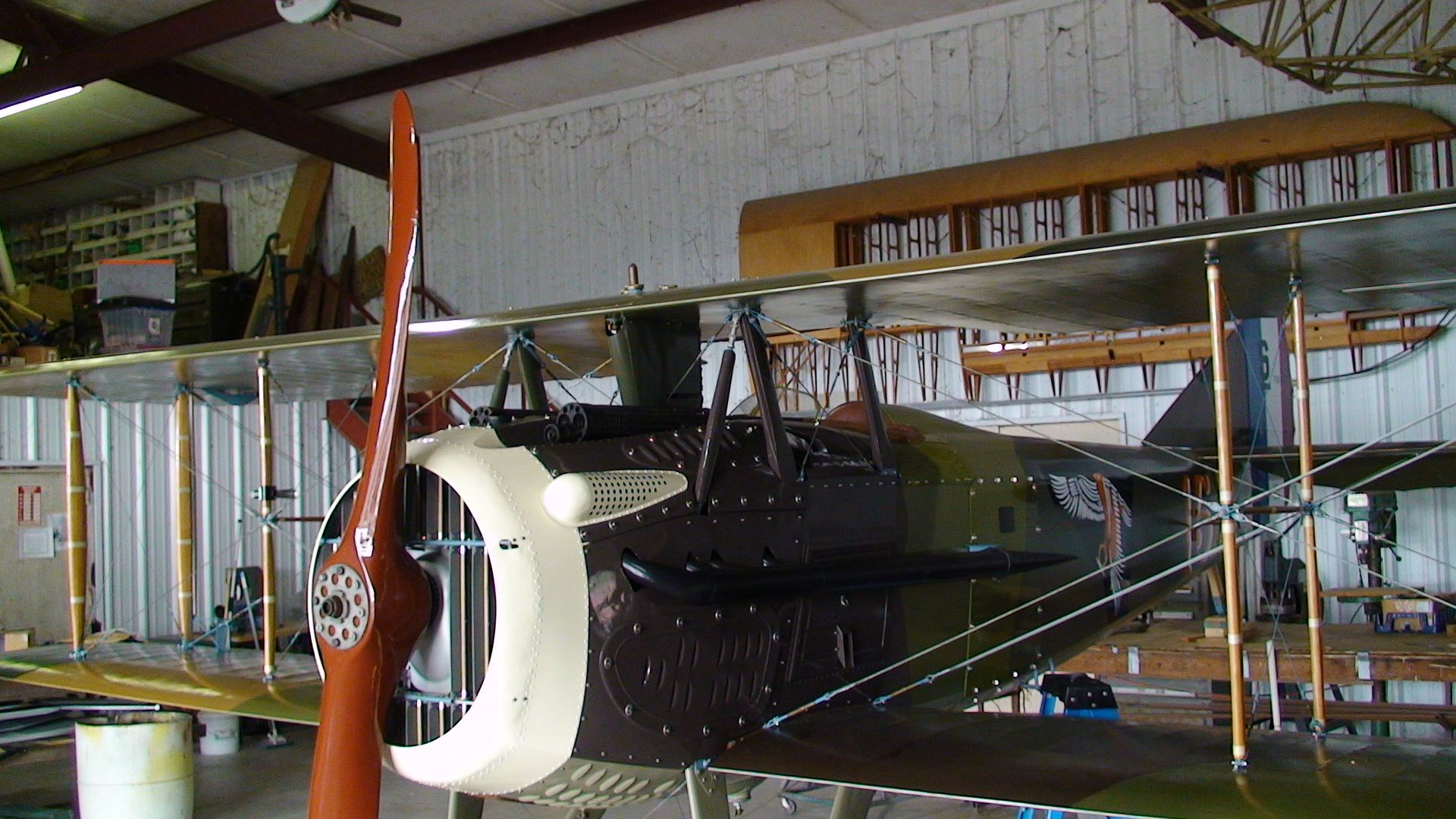

Don't beat me up but sheet metal is sheet metal. When I had a job this is what I did with sheet metal. All made from 4 x 8 sheets of aluminum of various gauges and tinsel strength. First pic shows parts the were mostly made over form blocks that were cut from steel sheets usually 3/8ths to 1/2 thick . The part was then cut rough size, annealed and formed to the steel form, excess was than trimmed down and finished off with a grinder/flapper wheel. The next pic shows the cowl, it was also made from a flat sheet. Formed around a wooden form to get general shape and I mean general. Ends were welded together and then with English wheel, shrinker, hammers and annealing and lots of time it became a 1917 French Spad XIII fighter cowl. There was a bit more to it then that but that's the jist of it. Next pic show some panels, done with the English wheel mostly to get the X Y radius's in the panel. The Last pic is prior to the covering of the aircraft. As I said sheet metal is sheet metal and it can be formed, of course Aluminum is easier then steel. Any questions on how or what I used to do what I'm happy to reply. Now to do my 40 sheet metal.

Last edited by Navy7797; 05-07-2013 at 05:13 PM. Reason: spellllling

-

05-07-2013 05:17 PM #33

That plane is bithin'! Gorgeous piece of work!

-

05-07-2013 09:02 PM #34

I just went through this thread again beginning to end twice. Such nice stuff, great work and imaginative. Congratulations to all you craftsmen.Nick

Brookville '32 hi-boy roadster

TriStar Pro Star 427 CID

-

05-07-2013 10:56 PM #35

Only one question here:

Got any more pics of that plane?.

Education is expensive. Keep that in mind, and you'll never be terribly upset when a project goes awry.

EG

-

05-08-2013 06:00 AM #36

That's a very cool plane, Navy! Who were you working for, building such a great, period correct replica? The combination of wood and metal craftsmanship is very nice to see, and I too would like to see more pictures of the process and especially the completed plane. I'd love to have one of the old wooden propellers hanging on the wall in that third picture! They are sooooo cool - precision shaping, often with some metal blended in on some of the later ones.Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

05-08-2013 07:03 AM #37

What I want to know the most-------how did you get 30 pictures in one post??????????

-

05-08-2013 07:41 AM #38

Wow! How many times do we have to answer this question for you, Jerry?? This has to be at least FIVE!

Bill even made a new Sticky with the details - read it here http://www.clubhotrod.com/shop-talk/...es-thread.html

Bill even made a new Sticky with the details - read it here http://www.clubhotrod.com/shop-talk/...es-thread.html

Last edited by rspears; 05-08-2013 at 08:25 AM.

Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

05-08-2013 09:08 AM #39

As a convenient service to my fellow CHR buddies, I have a little side business where if you email me pics, or links to your pics, and a few bucks donation, I will post as many pics in your designated thread as you specify. In lieu of monetary donations, pizza and beer are also accepted

Nick

Brookville '32 hi-boy roadster

TriStar Pro Star 427 CID

-

05-08-2013 10:06 AM #40

Roger-----

I'm not wanting to go to photo bucket----I have too many pictures that I don't want tp put someplace like that and quite a few that I would like to put places like this------

However, in order to post them here, I've got to downsize them and can only do 5 at a time--------seems to me that because of the difficulty of posting pics in threads , the number of posts with pictures have fallen off and been replaced by threads like the 3 word thingie----------this is supposed to be a HOTROD site, and everybody are saying we need pics--------------so they should fix/modify the system so that a modern day digital camera user could click a photo in a folder on their computer and upload it to a thread--------

I have thousands of cruise and major car show pics, thousands of race pics and machine shop/fab shop pics that are very detailed that I would be thrilled to share.

-

05-08-2013 10:40 AM #41

Well, I don't know what to tell you. You keep asking, "How did you post XX pictures in a thread?", and the only answer is "Use a third party host." Direct attachment is limited to five pictures, unless someone else has discovered another method that gets around the limits. I guess the answer is that you'll continue to ask, "How did you do that?", so from now on I'll ignore the question.

Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

05-08-2013 11:01 AM #42

Jerry, here's an easy fix for ya...

If you cant get the point across in 5 pics and more are needed, then just do another reply with 5 more pics and the word "More Pictures" in the body of the reply to satisfy the minimum letter requirement. It's a few more key strokes but nothing serious. Like everything else balance is the key in my mind. A thread with all text and no pics can get boring and dry just as an all pic thread with no text?

AND REMEMBER...

Last edited by M.T.1; 05-08-2013 at 11:35 AM.

duplicate account

-

05-08-2013 12:04 PM #43

Yeah MT1, but ya' gotta understand Jerry's told us in the past that he 1) takes all pictures in full resolution on an 18 megapixel camera, making each picture file 4 to 6MB in size; 2) he does not want to downsize his files, so he cannot post as direct attachments; and 3) he won't post to a third party host like Photobucket, Flickr, Shutterfly. Seems like Catch 22 - the system's just broken....

Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

05-08-2013 12:41 PM #44

Sorry I didn't know all the history here... Sometimes change is hard but it always opens the door to Opportunity! Over and out...duplicate account

-

05-08-2013 06:23 PM #45

Here's a few more. Also a little info, It took 4 years to build this plane and was built off original French plans that had the words converted to English, still used the metric system for all measurements. Engine in pic is 700 CID, the copper looking thing in the next pic is an oil cooler, next is sheetmetal in progress and last is the finished aircraft. Cost to buyer $500,000.oo That's alot of hotrods if you ask me.

13Likes

13Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Yep. And I seem to move 1 thing and it displaces something else with 1/2 of that landing on the workbench and then I forgot where I was going with this other thing and I'll see something else that...

1968 Plymouth Valiant 1st Gen HEMI