-

11-20-2013 04:30 AM #1

Drive Adapter for my HF Elec Pipe Threader

Doing the SWAG mod to my Harbor Freight tubing roller.

Harbor Freight Tubing Roller Electric Drive / Bottle Jack Kit

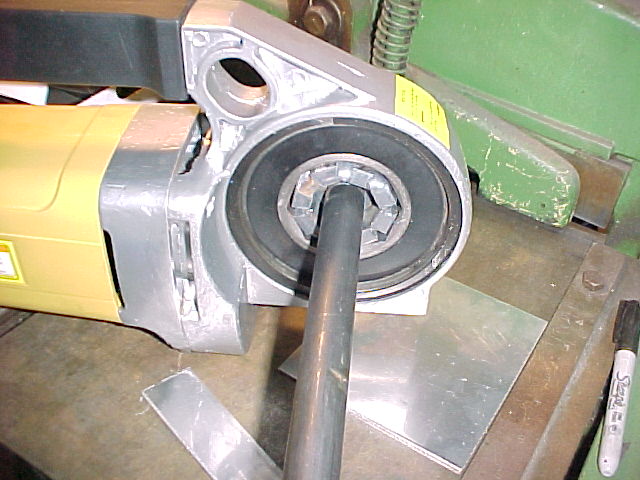

They say to just mash the 1/2" threading die onto the 3/4" drive shaft for the roller. I want to keep the 1/2" die usable so I designed an adapter to fit the octagon drive bore in the threader. This is an 8 sided bore. Would it have been to easy to make a 6 sided one?

The HF Pipe Threader.

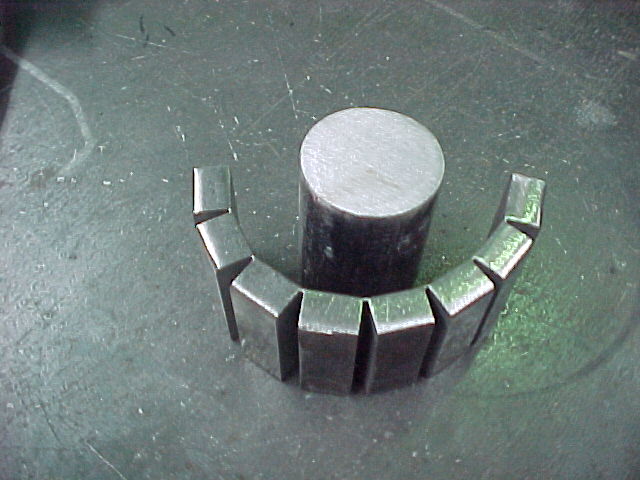

This is one of the original dies... 8 sides, not 6... Is this a "metric" hexagon?

I designed the adapter in 3D CAD so it was easy to get good dimensions. I first designed it by cutting 8 chunks of 3/8th's plate but thought it would be easier to assemble if they were all one piece.

We laid out all of the cut lines on a piece of 3/8 x 1 1/2" plate and clamped it to a small angle block.

Doing all of the cutting on the VBS was pretty quick with the layout lines and another block clamped on to guide the initial cut.

The spacing was .526 inches between the centers of the cut. With all of the cuts made.

We left about .030 at the bottom of the cut to hold all of the pieces together.

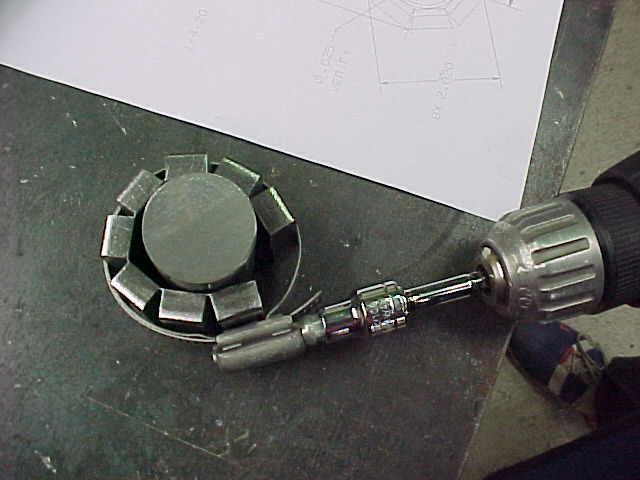

This is the "spindle" for the adapter. I cut a chunk of 1 1/4" dia. steel, cleaned it up in the lathe and bored a .75 hole thru the middle.

[imghttp://images107.fotki.com/v780/photos/5/904975/12609672/MVC005F-vi.jpg]http://[/img]

Drilled and tapped two holes on one end, 90 degrees apart, to clamp the adapter to the shaft.

Used the spindle to form the 3/8th's plate. This wasn't that easy. It took two sets of pliers to do the bending.

Getting it there...

The hose clamp pulled it down pretty close but we ended up using a hammer to get it the rest of the way.

Adjusting the fit. It fit real well on the first try.

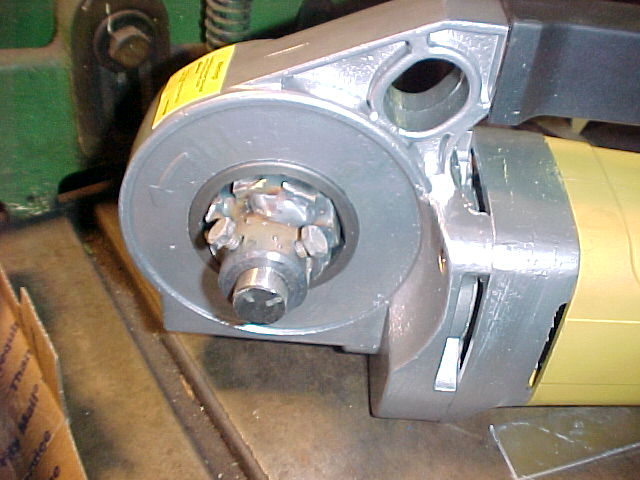

I welded everything up and checked the fit. Did a little clean up grinding and it was good to go. It's not pretty but it will do the job.

This thing got very hot during the welding but it still fit the shaft and the drive bore with no problems after it cooled.

I'll end up painting it black but this will do the job and I don't have to destroy the pipe tap from the kit.

Thanks for looking.

MarkIf money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

11-20-2013 06:15 AM #2

Nice job. Hope that HF threader lasts as long as it took you to build the adapter.

-

11-20-2013 06:29 AM #3

If money is the root of all evil... Women must be the fertilizer...

Link to my BAD AST Build Thread:

http://www.clubhotrod.com/suspension...van-build.html

-

11-20-2013 10:15 AM #4

Gotta love the creative minds on this site! Well Done!!"Where the people fear the government you have tyranny. Where the government fears the people you have liberty." John Basil Barnhil

-

11-20-2013 02:37 PM #5

Nice Job Mark! Good creative solution and it keeps the original die intact. But, I'm confused why they would want you to destroy that original die?

In any event, it came out great and as always thanks for thinking of us and sharing the pics!

Welcome to Club Hot Rod! The premier site for

everything to do with Hot Rod, Customs, Low Riders, Rat Rods, and more.

- » Members from all over the US and the world!

- » Help from all over the world for your questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and hundreds of thousands of posts!

YES! I want to register an account for free right now! p.s.: For registered members this ad will NOT show

3Likes

3Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Make the most of another birthday my friend.

Happy Birthday Mike Patterson