Thread: Project El-Cheepo Shop Heat

-

09-06-2015 04:42 PM #1

Project El-Cheepo Shop Heat

After several years of heating the shop with a torpedo heater and $4+/gal kerosene, I decided to build a waste oil heater for this winter. Our hot water heater lost an element so this seemed like a perfect time to break out the plans I've been holding onto for a few years. This is made using a tank from a 40 gallon water heater and a fairly simple gravity fed burner assembly. Here's the link if anyone is interested: Mother Earth: Waste Oil Heater1 Corinthians 1:27

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

09-06-2015 06:09 PM #2

Looks good, let us know how it works out.

I have been burning waste oil for several years now and my little Frankenstove has evolved considerably over time. It started out with a 55 Gallon drum outside the shop with a simple drip pipe that dripped oil onto a wood fire…..mostly just to have a way of getting rid of the waste oil the shop generated rather than paying to have it hauled off.

A few years ago I converted to a straight waste oil burner based on the plans you link to. It worked, but I had a few issues with it. Probably the biggest is that the basic design of the wood stove (rectangular) is just not as efficient as the cylinder you’re using. The other major problem was getting the oil to burn consistently and clean. The burner also need cleaning every other day or so. I ended up building two burners so that way I could have one out to clean and still have the stove running.

I lived with it for a couple of years, but it could get pretty aggravating and you definitely had to keep an eye on it. After doing some reading about using forced air on these I did a complete revamp on mine last year.

I’m still using the same “frying pan” burners the Mother Earth article shows.

The big difference is now rather than being fed air by draft, the air is forced thru the 2 ½” pipe directly in to the burner…….think forge (the pipe you see terminates about 2” above the burner). The fuel feed lines (3/8” copper tubing), go down the center of the air pipe so they can drip directly on the burner. I also built a couple of sight glasses which are invaluable to regulating the fuel going in.

The air is provided by a 110V blower motor and squirrel cage I picked up off E Bay. Going at full speed is way too much so I picked up a variable speed fan controller. Between controlling the fuel drip and the air I can get a really efficient burn.

You might notice that there are 2 fuel lines going into the air pipe. One is connected to the 55 Gal waste oil drum and the other is connected to a 4 gallon can of diesel fuel.

I start the stove by letting the diesel fuel run into the burner for a few seconds, then squirt just a bit of lighter fluid into that and throw in a match. Once the diesel fuel is burning good, I start a slow diesel fuel drip and turn the fan on. After a few minutes the burner is hot enough to start the waste oil drip and cut the diesel fuel. The 4 Gallons of diesel will last me anywhere from 2 weeks to a month. When I shut it down, I cut the waste oil and burn it on diesel for a few minutes to help clean the burner.

With the forced air the stove burns a lot more consistently and cleaner on the same amount of oil. I can also go up to 2 weeks between cleaning the burner. The heat exchanger in the stove pipe was also a good investment and really helps heat up the rest of the office. It takes a bit, but the setup can get the office area to 70 degrees eventually (on mornings when it's below freezing), which ain’t bad for not having any insulation.

The biggest problem I have with it is getting enough oil to get thru the winter now that I’m not working on customer cars. I did get lucky this year though. Now that oil prices are down they are charging to haul off waste oil instead of paying for it. That being the case, my buddy who runs a transmission shop let me haul off 120 gallons a couple of weeks ago.

Sorry if I hijacked this.

.Last edited by Mike P; 09-06-2015 at 06:27 PM.

I've NEVER seen a car come from the factory that couldn't be improved.....

-

09-06-2015 07:06 PM #3

This is awesome, Mike. Thanks for all the details and pictures, I think I'll follow your lead and set it up with forced air from the start.1 Corinthians 1:27

-

09-06-2015 07:42 PM #4

We had those torpedo heaters on the farm where I grew up, I could never take the noise or fumes.

I think you'll be glad if you go with the forced air. It will take some playing to get it set just right the first time (don't be afraid to move the burner around a bit under the forced air), but I think you'll find it's worth it.

One of the things I've read about people doing in a shop with a heater like yours is after it warms up to use a box fan to help circulate the heat around.

I don't know what your oil tank setup is going to be, but especially if the tank is outside and if you have fairly thick oil you might have an issue with it flowing on the cold mornings. The bigger the supply line to the stove (you can cut it down to a small size where it goes into the stove) and the more of it indoors where the oil can warm a bit on the way to the stove the better. I had some really thick oil for a time last year (used 20-50 plus some 90W mixed in) If you're oil is so thick it's causing a problem, you can cut it a bit with diesel fuel or ATF.

If you want I can try to get a picture of the sight glasses I made .....they are really invaluable for setting the fuel flow and making adjustments.

.

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

09-06-2015 08:11 PM #5

Neat setup, I know a couple of guys with a large used oil heater and large shop, they where spending a couple of days a week just collecting used oil! They had a outdoor 500 gal storage tank and complained about all shops saying it was "all oil" but they had antifreeze mixed in and on really cold weather the oil and antifreeze didn't seperate and stayed in sort of suspension, causing them to drain the 500 gallons several times a winter! So the idea of indoor storage sounds pretty inviting. However as neat as it sounds our prebuy on propane here in rural MO was $1.05 a gallon last month, right now thats pretty low heating costs for me. Cool heater however and great idea.Why is mine so big and yours so small, Chrysler FirePower

-

09-06-2015 09:23 PM #6

Yeah, burning waste oil can be interesting, unlike using propane or a fuel oil, your fuel changes every time you add more waste oil to the barrel. The waste oil seems to separate a bit over time with water on the bottom, then the heaver oil and the lighter oils towards the top.

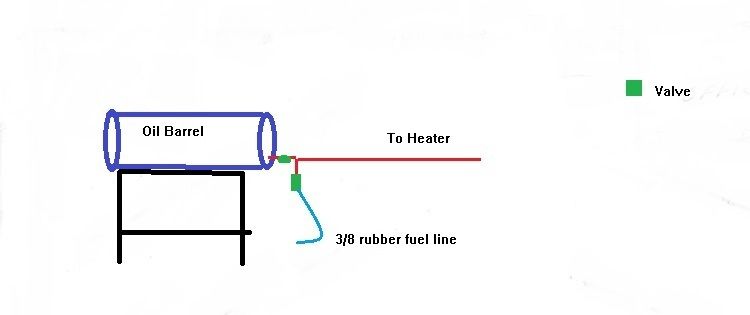

On my Barrel I put a "T" fitting where I draw the oil from. One side goes to the heater and the other side has a shutoff valve that I can use to drain out any water that might have connected over the summer.

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

09-07-2015 06:09 AM #7

Building my stove was a long learning curve so I figured I’d add a bit to maybe save you some time and better explain some of the stuff I said above.

Here is my basic oil tank setup. I also have another 55 gal and a 25 gallon drum sitting on the ground that I pump into the drum on the stand when needed. Besides the extra storage, it turns out that that having the drums on the ground also serve an important secondary function. Any suspect oil (water contaminated) goes in the drums on the ground. Over time the water will settle to the bottom. Whenever I draw from the drums the first few turns on the pump go into a bucket to see if there is any water (which I pump out until I get “clean” waste oil). Once the water is out then I transfer the oil into the supply drum. Basically the drums on the ground also act as oil/water separators.

The valve attached to the fuel line on the supply tank allows me to drain any water out of the supply drum. A friend at another shop lets me pour the contaminated water back in his drums to be hauled off.

Here is what I did for the diesel supply tank…..yup it’s an old 30 pound Freon bottle with a piece of pipe welded to the bottom and a cap on it turned upside down. A standard fitting (don’t remember the size) and flare fitting connect directly to the valve.

The diesel supply tank is well worth the effort. Most waste oil heater builders tell you to pour a little kerosene/diesel fuel into the bottom of the burner to get it started first thing in the day……from personal experience that can be a bit messy and if you don’t have enough fuel in it to get it hot enough to start burning oil, you have to let it cool down completely so you can try again. Besides being easier/cleaner to get the initial fuel in the burner to get it started, with the diesel supply you can run it on fuel until it is hot enough, and if you have a problem with thick or water contaminated oil you can let the diesel continue to drip to keep the burner hot. I have also found that when I shut it down for the day, if I shut off the waste oil and drip straight diesel for a few minuets it tends to burn off a lot the crap and cuts down how often I have to clean the burner.

My sight glasses are pretty basic, just a handful of pipe fittings. I drilled the sight holes thru the pipe nipple and then enlarged it with a die grinder. A short piece of ½” clear plastic tubing keeps any air from interfering with the flow. When I initially built these, I had a problem with the fuel running down the sides of the plastic tubing. What I ended up having to do was drill the top compression fitting (there the oil enters) completely thru just slightly larger than the copper tubing…….this doesn’t affect the compression fitting from clamping the tubing. With the copper tubing thru the fitting slightly the oil drips straight down.

Finally this is how I ran the fuel feed pipes into the air pipe. Basically I just drilled a couple of holes and welded in the correct size fitting. I also drilled these compression fittings so the tubing passes completely thru them and terminates an inch or two above the bottom of the air supply pipe. It can take a bit of tweaking to get the pipes centered in the pipe, but it just takes a bit of patience.

As I mentioned before I found the easiest way to light the stove is to run a bit diesel into the burner, then add a squirt of lighter fluid (either charcoal lighter fluid or cigarette lighter fluid) on top of that. Then it just lights off with a match.

I guess I got a little long winded again

.Last edited by Mike P; 09-08-2015 at 04:31 PM.

I've NEVER seen a car come from the factory that couldn't be improved.....

-

09-08-2015 12:39 PM #8

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,301

- Blog Entries

- 1

Last spring I purchased an old fuel oil furnace to put in the shop at my parent's place. My plan was to build a centrifuge and make fuel from used oil. I have about 400gal of used oil on hand. But, since I baught the house, the garage is already set up with NG in the garage. I'm trying to buy my old reznor hanging furnace back and then I'll be set up. I've used torpedo heaters for years and I know the smell you speak of. If you ever use brake clean in the shop, you best be shutting off your heat source.

Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

09-08-2015 02:40 PM #9

Nope, not long winded at all. You're saving me a lot of trial and error time. I owe you lunch.1 Corinthians 1:27

-

09-08-2015 04:23 PM #10

It seems as though we all have at one time or another resulted to the torpedo heaters. The other issue with them is they heat fast, too many btu's too quick so when they are running and smelling up the place your too hot but as soon as they shut off your too cold! Something more sized to the shop makes it way more comfortable!Why is mine so big and yours so small, Chrysler FirePower

-

11-10-2015 04:31 AM #11

I'm out in the shop this morning working on a couple little projects. It's been cold enough the last week or so to run the stove until the sun comes up. I remembered this thread and was wondering how your stove project is coming along?

.I've NEVER seen a car come from the factory that couldn't be improved.....

-

11-10-2015 06:28 AM #12

my torpedo heater has a thermostat . burns clean and keeps the shop toasty .

-

11-10-2015 07:32 AM #13

My new a/c- heat pump works perfectWhen I get to where I was goin, I forgot why I went there>

-

11-10-2015 12:26 PM #14

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,301

- Blog Entries

- 1

It hasn't been cold enough here to turn the shop heater on. Really weird....................Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

11-10-2015 02:38 PM #15

I've had a wood fire in the stove in the barn two or three mornings. I have a waste oil heater in the style falconvan's doing, but I need to put in a second chimney for it to get it going again. Mike's details have got me interested in getting it going again, maybe with a bit more sophistication than it had in the trial mode, but it worked pretty good with a five gallon bucket about ten feet above grade, flowing into the old hot water tank. Got the walls of the tank glowing red a few times....Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

7Likes

7Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

To the top

Where is everybody?