-

03-10-2016 08:31 PM #1

1947 Biederman Truck Fender Repairs

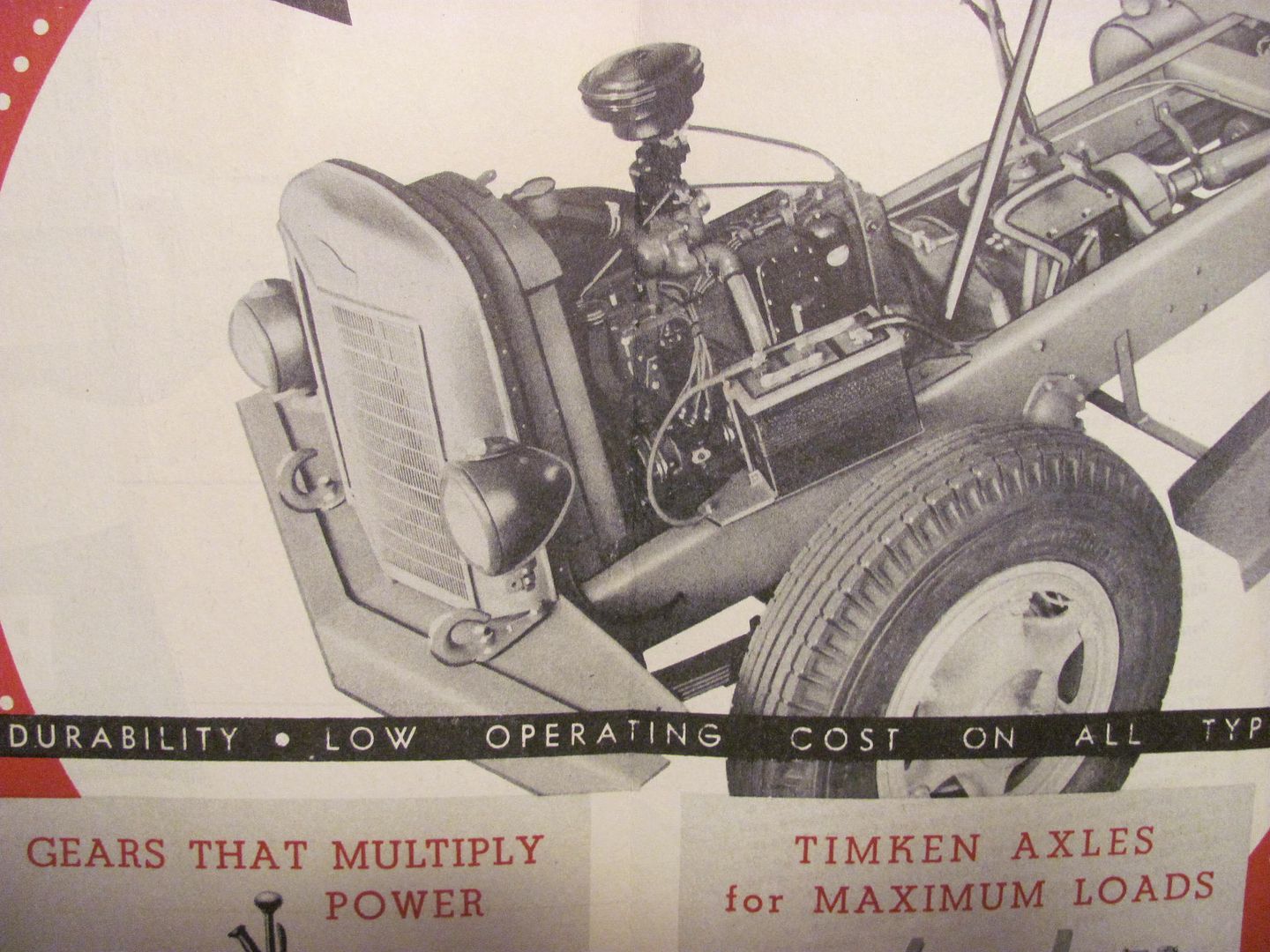

Tonight in the shop we started the repair work on the front fenders for the 1947 Biederman Truck, seen here for reference:

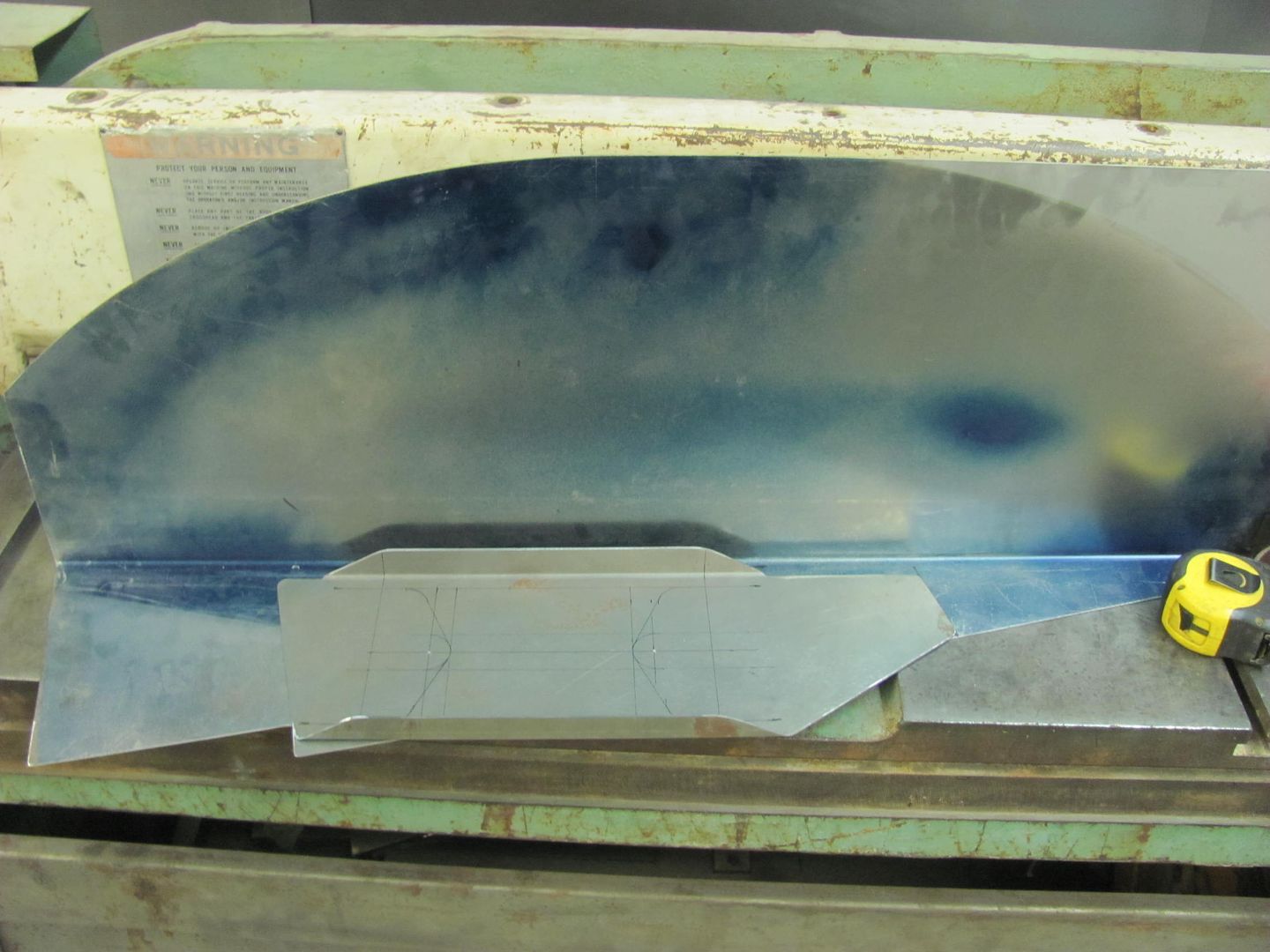

The fenders are made using 16 gauge steel, so this may be a bit challenging when we get to blocking and wheeling patches for the fenders themselves. In the meantime (while still waiting for the new English wheel) let's get started on the inner fenders. The driver's side is the worst, with so much rotted away that we couldn't get accurate dimensions. The passenger side was in much better condition, but just shy of 70 years has taken its toll in adding some wavy distortion. So we'll remake both sides for a better match.

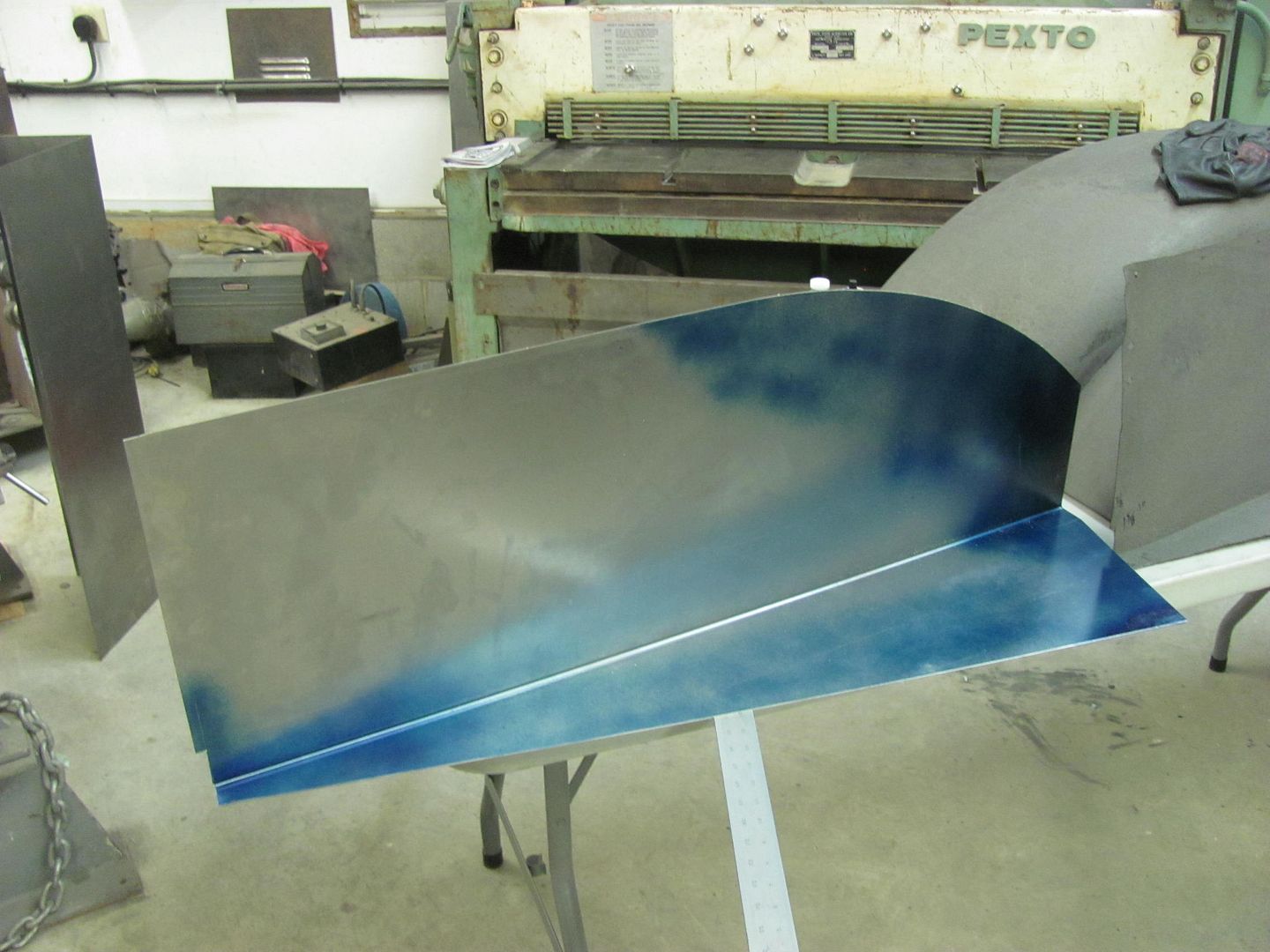

In order to get a more crisp bend on the 16 gauge steel, we used a tipping die in the Lennox to thin the metal at the line of the bend.

Bending in the Baileigh Magnetic Brake..

This detail shot shows how the thinning helps get a tighter bend..

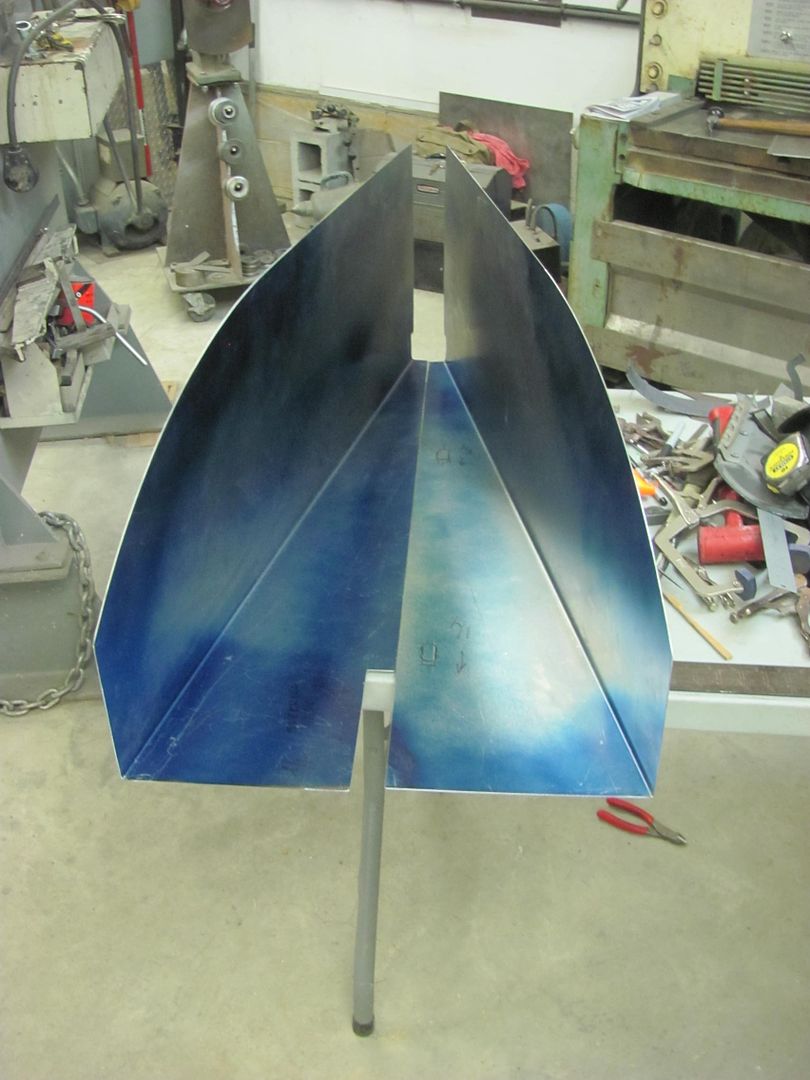

Next, we needed a profile template for the rear radius, so the kick shrinker is used on a folded 19 gauge strip to add the radius..

A flat folded strip works better than an angle as if you shrink too far in this direction.....

......you can simply shrink the back half to reverse the effect without the need for changing to the stretching die..

Now with an accurate pattern, we can use the template on the new inner fender..

All trimmed...

With the new clamped to the old, we can see what the years of abuse has done..

One down, one to go..Robert

-

Advertising

- Google Adsense

- REGISTERED USERS DO NOT SEE THIS AD

-

03-11-2016 12:24 AM #2

- Join Date

- Apr 2011

- Location

- Prairie City

- Car Year, Make, Model: 40 Ford Deluxe, 68 Corvette, 72&76 K30

- Posts

- 7,298

- Blog Entries

- 1

This will be nice to watch. You do amazing work.Ryan

1940 Ford Deluxe Tudor 354 Hemi 46RH Electric Blue w/multi-color flames, Ford 9" Residing in multiple pieces

1968 Corvette Coupe 5.9 Cummins Drag Car 11.43@130mph No stall leaving the line with 1250 rpm's and poor 2.2 60'

1972 Chevy K30 Longhorn P-pumped 24v Compound Turbos 47RH Just another money pit

1971 Camaro RS 5.3 BTR Stage 3 cam, SuperT10

Tire Sizes

-

03-11-2016 08:34 AM #3

As always - Thank You (and Kyle!)

What color is that truck? Would you know?

-

03-11-2016 09:11 AM #4

Not sure on the color but I can ask the owner next time I see him.Robert

-

03-11-2016 03:45 PM #5

Always something to learn from your posts, will

file away that ' thinning' technique. Could have

used that in past projects.

Richhttp://www.clubhotrod.com/hot-rod-bu...del-coupe.html

-

03-12-2016 07:20 PM #6

Today we got the second inner fender cut out, and took them both over for a test fit on the truck

The driver's side has a bolting plate in the middle of the frame for the steering box, so a relief notch was in order...

....as well as a bit of trimming for some clearance so that the paint won't be chipped off on the first test drive. The fabrication of these parts are done, and we should pick up the new Tommasini Wheeling Machine this coming weekend so we can get started on the fender patches..

Robert

-

03-14-2016 08:01 PM #7

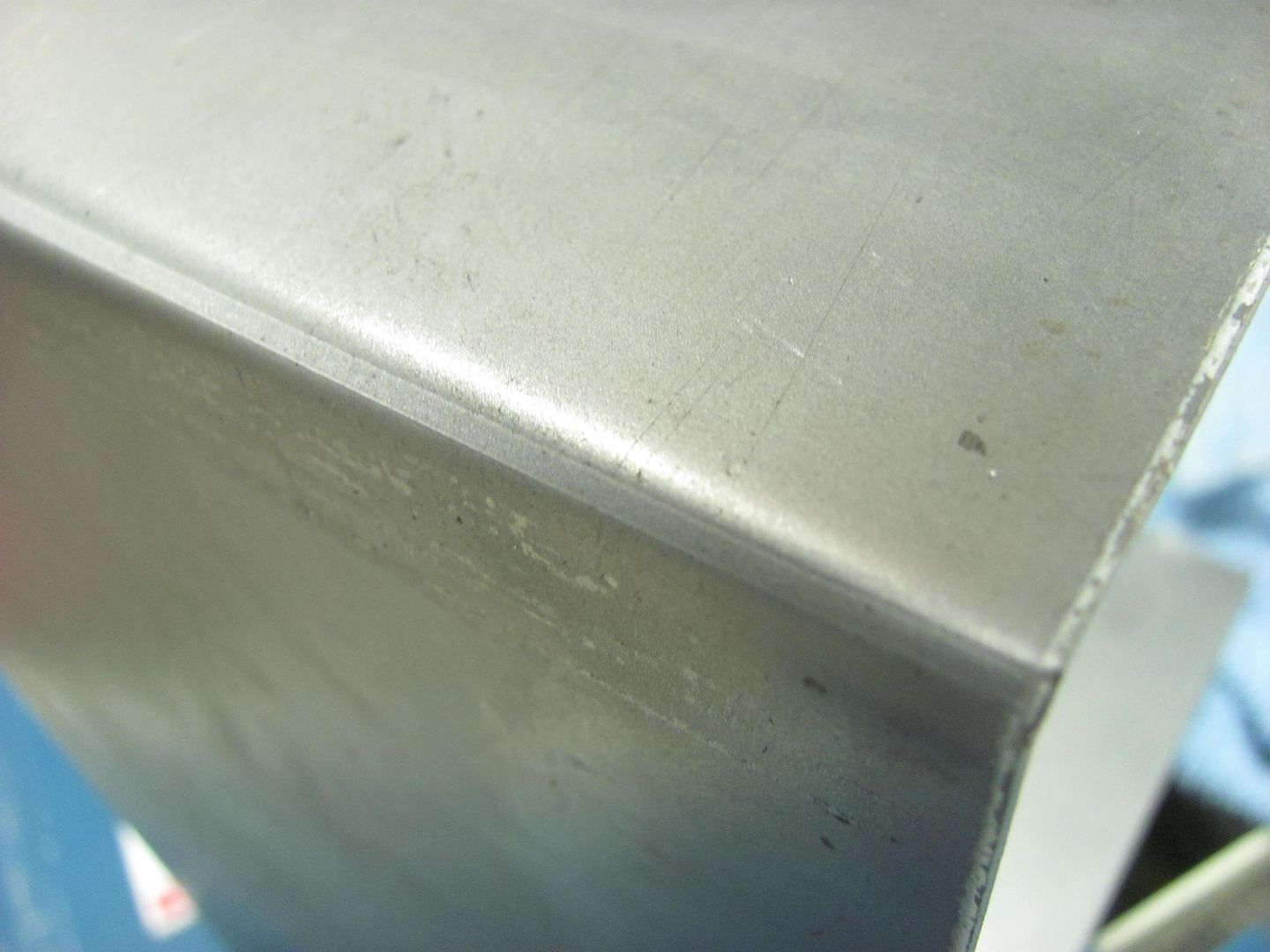

Had a question about placement of the thinning groove, so I thought I'd post the results of the test sample...

Originally Posted by WoodsTruck

Originally Posted by WoodsTruck

Here's the test from tonight. The 16 ga thickness measured out to about .057, at the "thinning" groove it was .053, so we lost about .004 in thickness, or less than 10%. Put the thinning groove on the outside for this bend, it tended to stretch the deformity back out again where it looks like it could be more readily cleaned up with a file..

So where the bending process allowed the groove to stretch back out....

...it also gave us a wider radius than when the thinning was placed on the inside of the bend...

So I'd say to use placement based on if a tighter radius is needed or whether you need it dressed outRobert

-

03-15-2016 06:53 AM #8

You got almost as many vise grips as I got guns!!!!!!!!!

-

03-15-2016 07:11 AM #9

Roger

Enjoy the little things in life, and you may look back one day and realize that they were really the BIG things.

-

03-15-2016 08:24 AM #10

Jerry, right at about 100 pair in various forms. (some have been purpose-modified) I tend to jump on bulk quantities at estate sales or auctions, you can never have enough.

Roger, it's been my experience that if you can explain something so that others can understand, you will better understand yourself. So I try to explain everything I can in my posts.. I do get corrected at times.....all part of the learning process.Last edited by MP&C; 03-15-2016 at 09:06 AM.

Robert

-

03-21-2016 07:10 PM #11

Great Post !!!!! Now if I can remember it next time I need it. Looking forward to this build.

-

07-01-2016 08:08 PM #12

John's getting ready for engine start ceremonies, so I guess I need to get off my duff here. To help out in that regard, next we'll fabricate the battery tray which I don't believe came with the truck when John got it. Here's the best we have for a pattern:

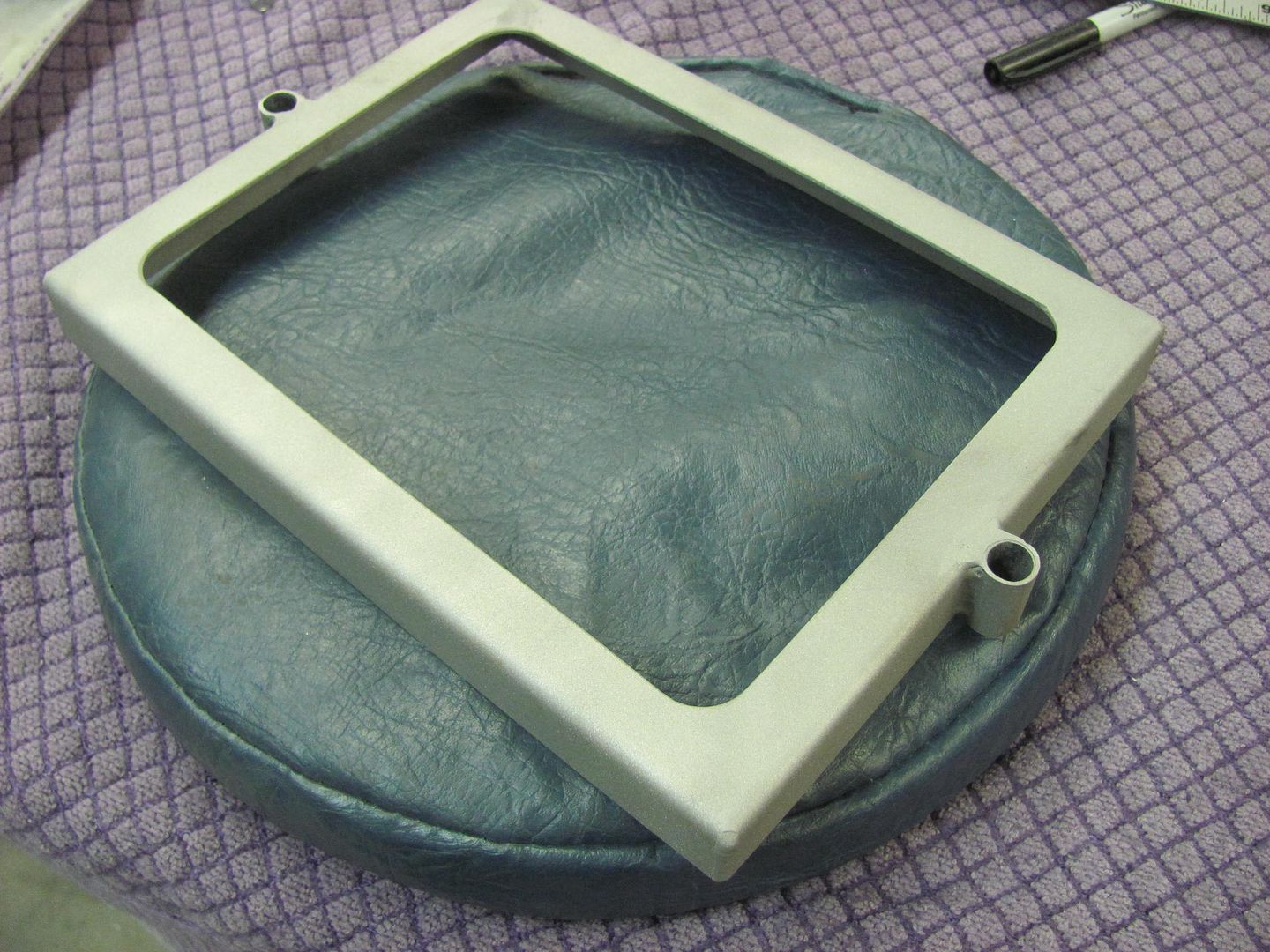

The hold down bracket for the prescribed Group 4 battery was with the truck, so we did some test fitting with the inner fender in place. It is a bit cramped for space, and John expressed concern of the availability of the Group 4 battery. Most local sources only carry the Group 1 in stock, which would also be a better fit.. So out with the old...

I did miss getting in the flat pictures, but here is the freshly folded and welded hold down bracket for the new battery size.

All trimmed and prepped for paint..

Comparing the new to the old...

Next will be the new battery tray.Robert

-

07-04-2016 11:45 AM #13

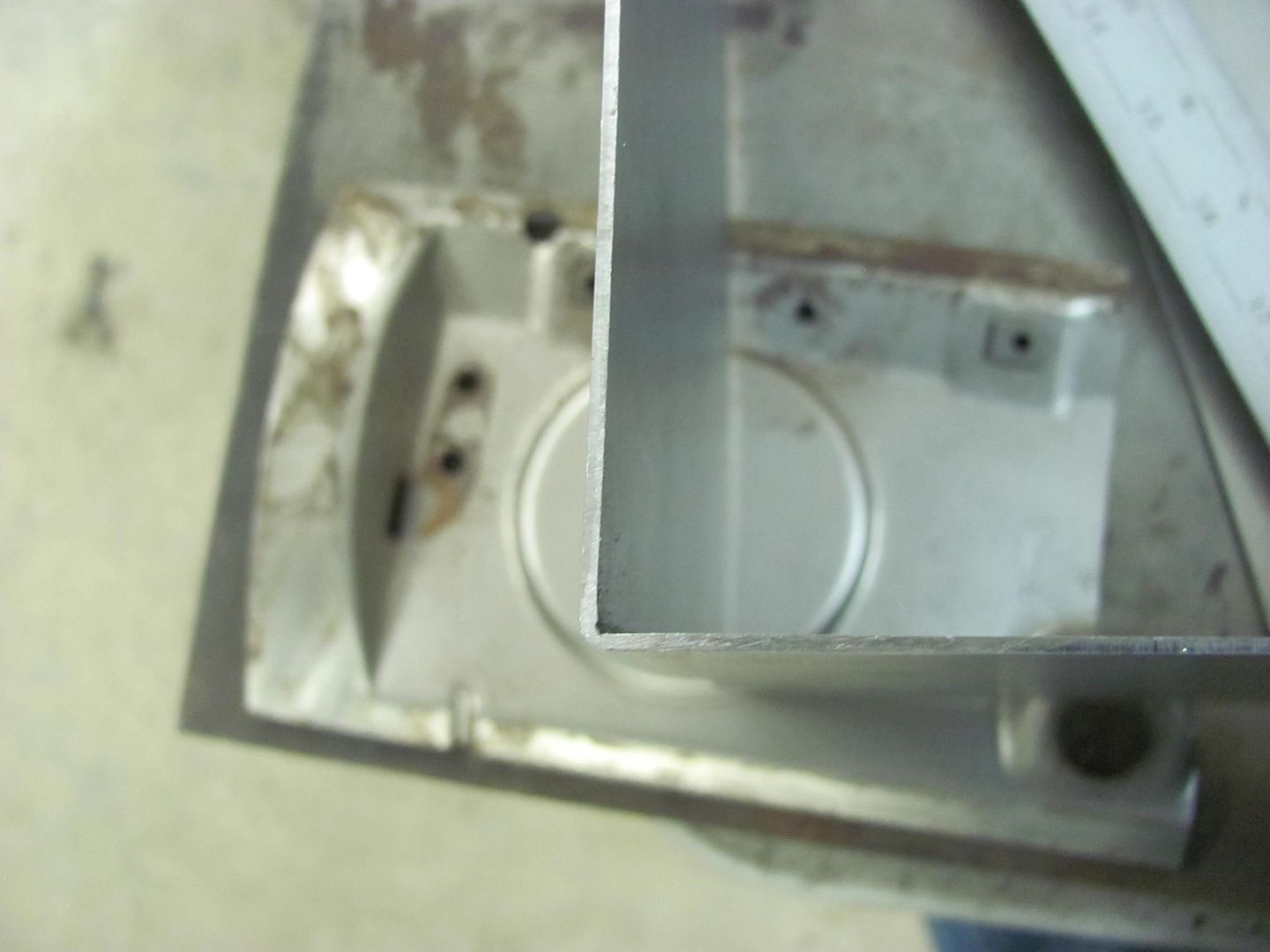

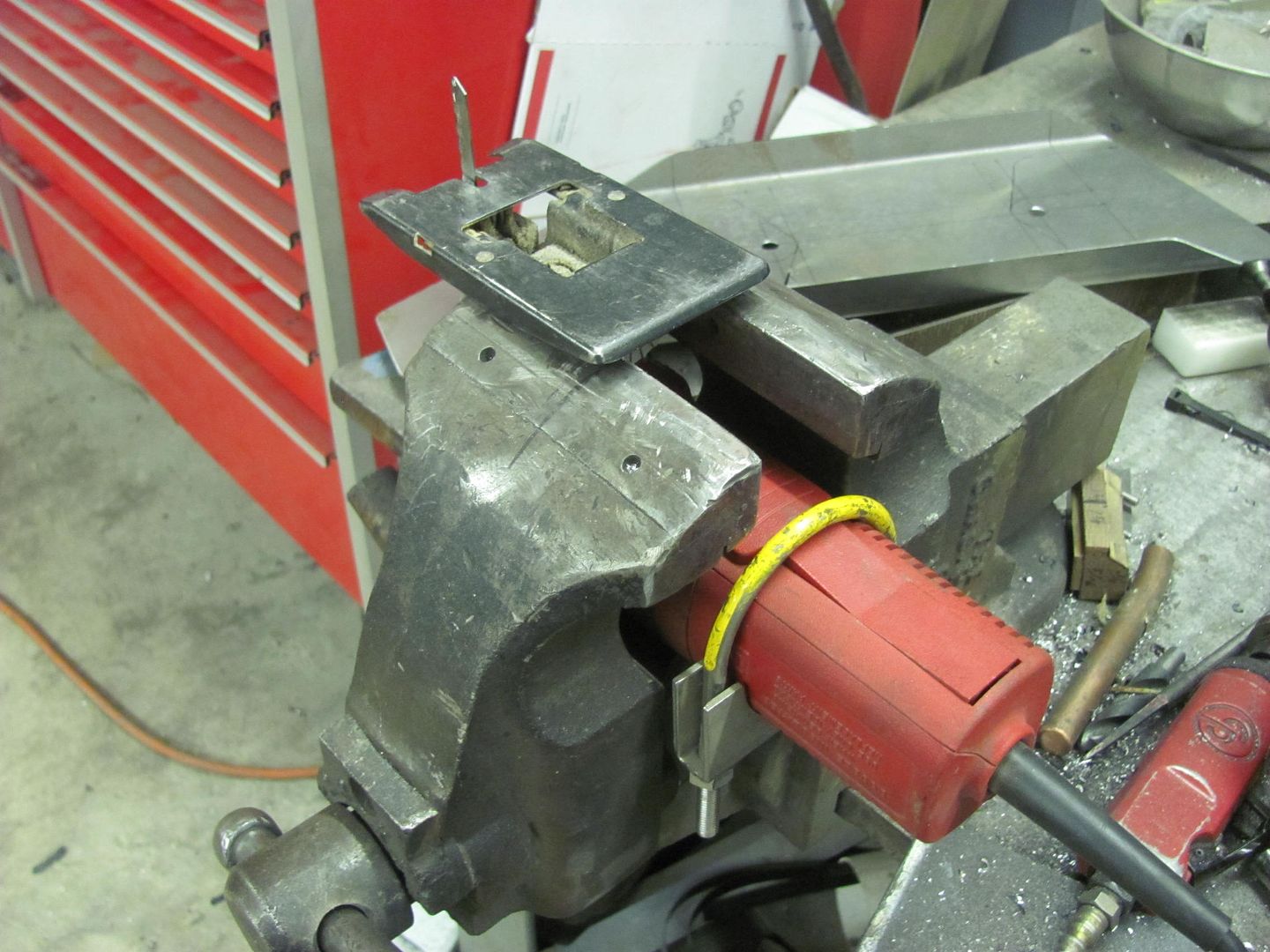

...and now for the battery tray, shown here cut to size and sides folded up...

For the end folds, the cut was started using a .035 cutoff wheel..

...and our trusty jig saw again...

Both ends complete, and frame holes have been piloted. Once checked to the hole spacing on the frame they can be drilled out for the 3/8 bolts.

Robert

-

07-04-2016 04:18 PM #14

Ummm...I'm not the brightest crayon in the box...but I can't see how you started the jigsaw blade in the cut.

I've always drilled a hole slightly wider than the blade to start a cut like that, as I've found the blade just bounces about all over the place if I try to ease it in from a virtually parallel position.johnboy

Mountain man. (Retired.)

Some mistakes are too much fun to be made only once.

I don't know everything about anything, and I don't know anything about lots of things.

'47 Ford sedan. 350 -- 350, Jaguar irs + ifs.

'49 Morris Minor. Datsun 1500cc, 5sp manual, Marina front axle, Nissan rear axle.

'51 Ford school bus. Chev 400 ci Vortec 5 sp manual + Gearvendors 2sp, 2000 Chev lwb dually chassis and axles.

'64 A.C. Cobra replica. Ford 429, C6 auto, Torana ifs, Jaguar irs.

-

07-04-2016 05:43 PM #15

The dark shadow in the upper right corner of the picture is the die grinder with an .035 thick cut off wheel that was used to make the initial slit. Thought the photographer was going to get those details in the picture as well but he was slacking today..

Robert

Welcome to Club Hot Rod! The premier site for

everything to do with Hot Rod, Customs, Low Riders, Rat Rods, and more.

- » Members from all over the US and the world!

- » Help from all over the world for your questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and hundreds of thousands of posts!

YES! I want to register an account for free right now! p.s.: For registered members this ad will NOT show

260Likes

260Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks Reply With Quote

Reply With Quote

Hope you enjoy your day, Mike, and celebrate YOU!

Happy Birthday Mike Patterson